I’m intrigued by the chain of historical inventions that led to the modern detonator.

Detonators for explosive charges evolved from firearm trigger mechanisms and I see these as an invention continuum, with one leading to another. Alongside these mechanical inventions, chemical discovery runs as a parallel track, particularly the discovery or primary explosives and high explosives, which detonate by shock (gunpowder being a low explosive which explodes by deflagration)

Initially, I guess the first “initiators” were simply burning fuzes which transmitted a flame to gunpowder. However there is some early mention of a some victim operated mechanisms perhaps using friction devices or steel and flint levers. See Chinese IEDs here.

To help undertsand the chain of scientific, chemical, physical and mechanical inventions that took us down this path the folloing rough time line might be useful:

Pre 1400 – Burning fuzes of various types, igniting gunpowder by burning.

Early to mid Mid 1400s – Invention of the matchlock mechanism to initiate firearms. Note that this was definitely a European invention – the Portuguese took matchlocks and introduced them to China and Japan. (The story of how the Japanese obtained and reverse engineered the matchlock will be the subject of a future post) .

About 1500 – Invention of the wheel-lock, possibly by Leonardo Da Vinci, which introduces a new mechanical action to apply a burning fuze to a specific point.

1540 – The snaplock was invented, using a flint initiator. This was a precursor to the more sophisticated flintlock

1558 – The snaphaunce was developed which incorporated a mechanism for keeping the gunpowder covered until the flint fell, when the cover is opened automatically. The cover is called the frizzen.

1588, a time initiated system used by Giambelli to explode the “Hoop”, with a timing mechanism causing ((I’m guessing with a snaplock or snaphance) to initiate the charge.

1602 Gold fulminate (the first primary/high explosive) discovered by John Tholde of Hesse.

1610 – The first flintlock initiation system developed The flintlock mechanism is an evolution of the snaphaunce whereby the frizzen is not only a cover for the pan of gunpowder, but also the steel face on which the flint strikes to cause sparks.

1659 Robert Hooke and Thomas Willis discover the primary explosive characteristic of Gold hydrazide

1745 Dr Watson of the Royal Society showed that an electrical spark from a Leyden jar could initiate a small blackpowder charge.

1750 Benjamin Franklin initiates gunpowder with an electrical spark and makes small paper tubes of powder with two wires inserted and a spark gap created.

1788 Silver fulminate was first made by French chemist Berthollet.

1776 – American revolutionaries used adapted firearm mechanism to make contact mines consisting of “kegs” of gunpowder which were floated down rivers. The kegs have fastened to the lid a wooden arm which when it touched a target ship connected to an iron pin, engaging a flintlock device from an adapted firearm, causing the main charge to explode. Note the similarities in principle to much later IED initiators here. I’ll post some images of these “kegs’ in future posts.

1777 – Italian scientist Alesandro Volta, describes how he had fired pistols, muskets and a ”mine subacquee” (underwater mine) electrically – it appears he used a hot wire to initiate a glass bulb full of a flammable gas.

1782 – Another Italian scientist, Cavallo, described detonation of a charge of gunpowder, electrically, using an incandescent wire embedded in the powder

1795 – Cavallo uses another method, using gunpowder mixed with steel filings, with two electrical probes embedded in it.

1799 – Fulminate of mercury, a primary explosive later used in detonators was first prepared by Charles Howard. Interesting reports on his experiments are here and I think its very significant indeed that Howard actually tested electrical initiation of mercury fulminate. I note also that Howard refers to French scientists electrically initiating some form of potassium chloride based explosive in the late 1700s. Howard’s description of the experiments he conducted with mercury fulminate are fascinating – clearly he hoped he had invented an alternative to gunpowder, but initiating mercury fulminate within a gun caused some catastrophic damage to his equipment! There is a great description of how Howard measured the volume of gas produced from a specific quantity of the explosive.

1812 – The Russian military scientist Pavel Schilling developed an electrically initiated IED, as a mine. My apologies, in earlier posts I credited this to others later in the 19th Century, and I have only recently discovered Schilling’s (and Volta’s, and Howard’s) technologies. Schilling gradually improved the associated technologies, insulating wire with tarred hemp and copper tubing, and devising a carbon arc initiator.

Also in 1812 – Prussian scientist Sommerring improved the insulation of electrical wire, using rubber and varnish, allowing further capabilities to be developed in initiating explosives.

1820 – American scientist Robert Hare, worked on electrical initiation of flammable gases. Hare also developed a “plunger” type galvanic machine for producing electrical charges for this purpose.

1822 – Hare used a hotwire embedded in a pyrotechnic mixture to initiate a blackpowder charge. In the 1830s Hare also produced a tin tube container packed with powder and with an ignition wire for rock blasting but foresaw the military importance of command initiated explosive charges.

1829 – A young Samuel Colt initiated an under water charge electrically perhaps using a tarred copper wire.

1831 – The Bickford burning fuze was invented, taking away the guess work about time delays for burning fuses.

1837 Colonel (later General) Pasley of the Royal Engineers developed chemical then an electrical initiation mechanism to explode gunpowder charges under water. Pasley’s work appears to have been prompted by reading a newspaper report of an “ordnance accident”, in Russia, when Tsar Nicholas I narrowly escaped death when viewing a demonstration of electrically initiated gunpowder charges used to blow up a bridge, presumably developed by Schilling. Pasley read the article and then sought the advice of English scientist Charles Wheatstone to consider how he might use the same concept. Pasley’s contributions to military engineering are huge, and his explosive related inventions are very significant if only a part of that broader work. I have yet to find details of Pasley’s chemical fuzes, but his electrical initiation mechanisms used electrically heated platinum wire, with the electricity provided by early galvanic cells. Pasley solved the problem of insulating the wires so they could be used under water, by coating wire with gutta percha. The platinum wire (or foil) provided enough heat to initiate the gunpowder it was embedded in. However some reports state that the electrical system caused a detonation by a “galvanic spark” so the actual mechanism is still a little unclear. I’m very intrigued by the chemical fuzes and how they worked, given the nature of the underwater tasks that Pasley developed the explosives for. I think it likely that there would have been some form of command pull to initiate the chemical reaction once the divers were clear and safe. Chemically the reaction may have been similar to Nobel’s (later? ) designs.

1830s – Immanuel Nobel developed chemical initiation mechanisms to initiate gunpowder. The mechanisms used a glass vial containing suplhuric acid, which when broken (usually by an enemy) caused the acid to fall by gravity onto potassium chlorate, which ignited and caused surrounding gunpowder to initiate. These were confusingly called “Jacobi” fuzes after the Russian scientist for whom Nobel worked. Jacobi led the Russian “armed services committee for underwater experiments” between 1839 and 1856. It is clear that Jacobi’s secrecy prevented international publication of the scientific achievements he made in electrical initiation. Jacobi’s work from 1839 seems to have been prompted by both Schilling and Pasley. What is significant is a reference I have found to Jacobi developing “mercury connecting devices” which probably mean some form of mercury electrical switch to initiate contact mines in the 1850s.

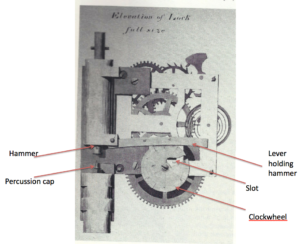

1830s, Mercury fulminate was used in copper caps used as firearm initiators taking the place of flint, and making the process of initiating a firearm much less dependent on flint and the weather.

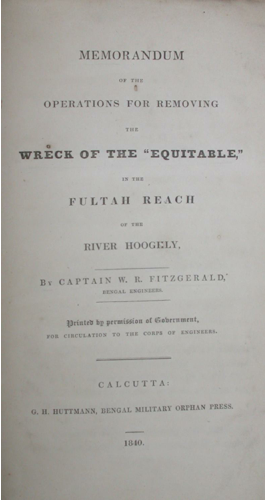

1839 – Other British Royal Engineer salvage operations in Bermuda and in Bengal on the Hoogly river used electrically initiated charges. I have a great piece of reseacrh to blog about with regard to the Hoogly river operation.

1840s – Samuel Colt conducted extensive work on highly complex electrical initiation systems for sea and river mines.

1848 – Werner von Siemens developed electrically initiated sea mines.

1863 – Alfred Nobel (Immanuel Nobel’s son) published his patent for a practical detonator to initiate nitro-glycerine. Note that this was four years before his patent for dynamite. In modern parlance this was a non electric blasting cap, itself initiated with burning fuse. The detonator consisted of a small blackpowder charge, a wooden plug and a small quantity of nitroglycerine held within a metal cylinder. The black powder is initiated by a burning fuze, which pushes the wooden plug down the cylinder, which then strikes the niroglycerine with kinetic energy.

1865 – Nobel refined his detonator design significantly, with a small metal tube containing mercury fulminate

1868. H. Julius Smith produces a detonator that uses a spark gap and mercury fulminate.

1875 The electrical detonator using a hot filament was developed independently by Gardiner and Smith